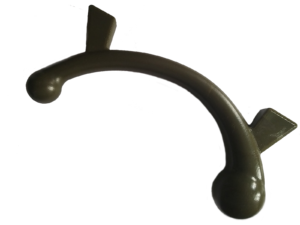

Precision Casting

Investment Casting

We don’t just cast. Our aim is to find the optimum solution for you in the triangle of design, production method and material selection. We are ready to work together to make our customers competitive in material selection, design and production methods improvements.

We produce in line with the quality standards specified by our customers, and deliver the products with material tests and measurement controls.

• Material Analysis

• Hardness measurements

• Non-destructive testing

• Dimensional controls

What is Investment Casting?

PRECISION CASTING, also known as ceramic mold casting, lost wax method, offers completely different advantages from traditional casting.

High dimensional accuracy, high surface quality, susceptibility to complex geometries and being able to cast all kinds of alloys can be listed as the first advantages that come to mind.

Investment casting consists of a series of processes using liquid refractory. In this casting method, wax or plastic is pressed into a mold, including tensile tolerances, to give the desired shape. Models prepared in this way are arranged in clusters around the runner. This inflorescence is covered with a thin refractory. The wax is melted and taken out, and this fine refractory is sintered at approximately 1000°C. This formed shell is cast while it is hot. Then the ceramic shell is broken and cast in the form of a cluster is taken, and the remaining ceramics are cleaned. The surface of the obtained part is very clean compared to other casting methods and often does not need to be processed.

Areas of Investment Casting

Investment Casting is very suitable for mass production of metals and alloys in small sizes. It is ideal for parts with complex shapes as it requires little or no post-machining and heat treatment. While the investment casting method is applied in many places, the most known ones are; Weapon parts, engine parts, pump valve parts, textile machine parts, automotive parts, medical parts, ship supply industry parts, air conditioning products, combi honeycomb parts, construction decoration parts, blades of gas turbines and jet engines, etc. countable.